Fixed:86-0755-81155045

MOBILE phone:86-13825293167

Email:zhipz@163.com

Address: Guangdong Province, Dongguan City, Fenggang Town, Yantian cloth ridge industrial zone

Source of the article:XinXin Injection Molding Machinery Co.,Ltd issuing time:2016-06-29

Update time: 2016-10-21

PE as the crystalline material, moisture absorption, not more than 0.01%, thereforeThe disc injection molding machineIn front of the injection molding processing without dry processing.

PE molecular chain flexibility, small key inter-atomic forces, the melt viscosity is low, liquidity is wonderful, soThe disc injection molding machineMolding without too much stress can produce thin wall long process products.

Large range of shrinkage rate of PE, shrinkage value is large, clear direction, LDPE shrinkage rate is approximately 1.22%, HDPE, shrinkage rate is about 1.5%.So easily deformed,The disc injection molding machineThe influence of the mold cooling conditions on the shrinkage rate is very big, so should control the mold temperature, keep the uniformity and stability of cooling.

The crystallization of PE ability is high,The disc injection molding machineThe temperature of the mould of plastic parts crystallization condition has a great influence.High mold temperature, melt slowly cooling, plastic pieces of high crystallinity, strength is high.

The melting point of PE is not high, but the specific heat capacity is larger, so the plasticizing still need to consume more calories, so the requirementThe disc injection molding machinePlasticizing unit should have large heating power, in order to improve the production efficiency.

PE softening temperature range is small, and easy oxidation of the melt, so should avoid as far as possible in shaping the melt contact with oxygen, so as not to reduce the quality of plastic parts.

PE quality of a material soft parts, and easy mold release, so when the parts have a shallow lateral recess can strong demoulding.

PE of non-newtonian melt is not obvious, the change of the shear rate on viscosity is small, the influence of PE melt viscosity is affected by temperature is smaller.

PE melt cooling speed slower, so must be cooled sufficiently.The disc injection molding machineUsing mold should have good cooling system.

If PE melt in using direct injection inlet feed, increasing stress and the increase of search is not uniform and clear direction deformation, so choose the inlet parameters should be paid attention to.

Forming with wider temperature of PE, under the flow state, a small fluctuations in temperature has no effect on injection molding.

PE has good thermal stability, in 300 degrees commonly the following decomposition has no obvious phenomenon, won't make any difference on quality.

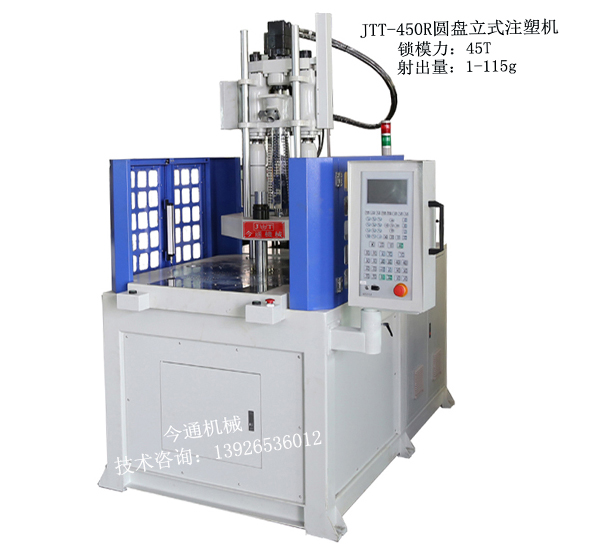

The disc injection molding machineWidely used in baby toys, computers, the toothbrush, ornaments, brooches, antenna, badges, buttons, charger, electric appliances, stationery, furniture, sporting goods, gear, tableware, surface, small decorations, plastic flower, building materials, automobile, instruments, electronic parts, splice pieces, telecom, key chain, toys, plug, connector, switch, backpacks, SuPing connectors, pen, cosmetic joint.

Recommended reading:Vertical injection molding machine,verticalInjection molding machine brands,Vertical injection molding machine manufacturers。

Previous:Looking back at...